姓名:孫偉振

職稱:教授(博士生導師)

地址:華東理工大學實驗十六樓509室(徐彙校區)

電話:021-64253027

傳真:021-64253528

Email:sunwz@ecust.edu.cn

【教育背景】

1995-1999 華東理工大學,化學工藝本科

2001-2004 華東理工大學,化學工程碩士

2005-2009 華東理工大學,化學工程博士

【工作經曆】

1999至2001年,青島鋼鐵集團公司潤滑油廠任副廠長。

2004年至今,華東理工大學化學工程聯合國家重點實驗室工作,曆任助教、講師、副教授、教授。

2012至2013年,美國加州大學伯克利分校化工系,跟随Berend Smit教授從事分子模拟研究。

【所獲榮譽】

上海市技術發明一等獎(2014)

中國石油和化學工業聯合會科技進步一等獎(2018)

【學術任職】

美國化學工程師學會(AIChE)高級會員

中國化工學會會員

【研究方向】

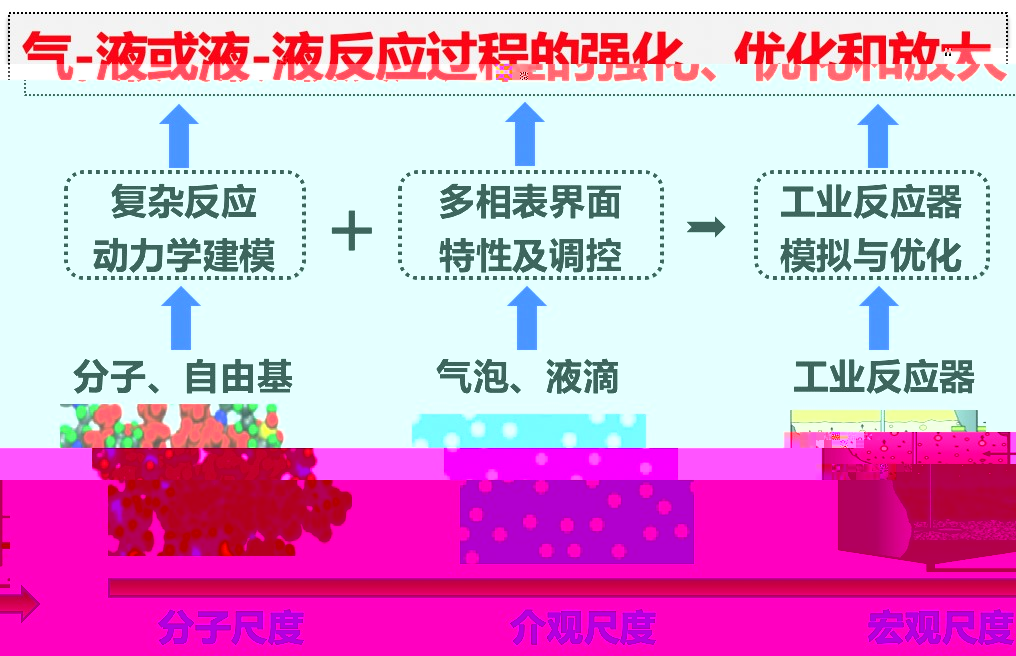

1、化工過程開發

大型工業反應器開發、化工過程強化與優化等,包括(1)氣-液反應體系如芳烴(PX、MX)氧化、國防材料聚酰亞胺單體合成等;(2)液-液反應體系如離子液體/硫酸催化C4烷基化合成高品質清潔汽油等;(3)高值精細化學品(日化産品、食品添加劑)的連續化工藝改造等。

2、多相反應表界面調控

研究多相反應(液-液、氣-液、氣-固、氣-液-固)表界面上小分子的溶解、擴散、自組織等表界面特性,理解并指導反應過程的強化和催化劑設計。研究對象包括離子液體催化C4烷基化、烴類液相氧化、乙烷氧氯化等。

3、多尺度模拟計算

常規蒙特卡羅(MC)、分子動力學(MD)模拟以及基于反應力場的分子動力學(ReaxFF-MD)模拟(用于研究燃燒、裂解等快反應);複雜反應體系的動力學建模;反應器模拟;化工流程模拟。

4、材料化學工程

可控制備MOF、ZIF、COF等納米多孔材料,研究其在化工分離、醫學殺菌和載藥、锂離子電池等方面的應用。合成各類新型離子液體(IL)用于催化反應和醫學殺菌。

【代表性論文】(第一或通訊作者)

(一)多相表界面

1)Promoting the Sulfuric Acid Catalyzed Isobutane Alkylation by Quaternary Ammonium Ionic Liquids. AIChE Journal, 2020, 66: e16979.

2)Towards an Understanding of the Microstructure and Interfacial Properties of the Ionic Liquid/Sulfuric Acid Catalyst in Liquid-Liquid Reactions. Chemical Engineering Science, 2019, 205: 287-298.

3)Probing Interfacial Behaviors of Brønsted Acidic Ionic Liquids Improved Isobutane Alkylation with C4 Olefin Catalyzed by Sulfuric Acid. Chemical Engineering Journal, 2019, 377: 119744.

4)Experimental and Modeling Study of Isobutane Alkylation with C4 Olefin Catalyzed by Brønsted Acidic Ionic Liquid/Sulfuric Acid. Chemical Engineering Journal, 2019, 377: 119578.

5)Understanding Structure-Property Relationship of SO3H-Functionalized Ionic Liquids together with Sulfuric Acid in Catalyzing Isobutane Alkylation with C4 Olefin. Industrial & Engineering Chemistry Research, 2018, 57: 15310-15318.

6)Microstructures of the Sulfonic Acid-Functionalized Ionic Liquid/Sulfuric Acid and Their Interactions: A Perspective from the Isobutane Alkylation. Journal of Physical Chemistry B, 2018, 122: 1460-1470.

7)Understanding Interfacial Behaviors of Isobutane Alkylation with C4 Olefin Catalyzed by Sulfuric Acid or Ionic Liquids. AIChE Journal, 2018, 64: 950-960.

8)Screening of Imidazolium Ionic Liquids for the Isobutane Alkylation Based on Molecular Dynamic Simulation. Chemical Engineering Science, 2018, 183: 115-122.

9)Modeling of the Interfacial Behaviors for the Isobutane Alkylation with C4 Olefin Using Ionic Liquid as Catalyst. Chemical Engineering Science, 2017, 166: 42-52.

(二)反應動力學、反應器

10)Multiscale Modeling of Isobutane Alkylation with Mixed C4 Olefins Using Sulfuric Acid as Catalyst. Industrial & Engineering Chemistry Research, 2019, 58: 6340-6349.

11)Multi-Scale Modeling of Isobutane Alkylation with 2-Butene Using Composite Ionic Liquids as Catalyst. Chemical Engineering Science, 2018, 186: 209-218.

12)Experimental Study and Modeling of Homogenous Catalytic Oxidation of m-Xylene to Isophthalic Acid. Industrial & Engineering Chemistry Research, 2015, 54: 3293-3298.

13)Modeling of CO2-assisted Liquid Phase Oxidation of para-Xylene Catalyzed by Transition Met/Bromide. Chemical Engineering Science, 2015, 127: 52-59.

14)Liquid Phase Oxidation of Alkyl Aromatics at Low Oxygen Partial Pressures. Chemical Engineering Journal, 2015, 278: 533-540.

15)Alkylation Kinetics of Isobutane by C4 Olefins Using Sulfuric Acid as Catalyst. Industrial & Engineering Chemistry Research, 2013, 52: 15262-15269.

16)Simulation of Secondary Oxidation of p-Xylene in Liquid Phase. Industrial & Engineering Chemistry Research. 2011, 50: 2548-2553.

(三)材料化學工程(多孔材料、離子液體)

17)Killing Oral Bacteria Using Metal-Organic Frameworks. Industrial & Engineering Chemistry Research, 2020, 59: 1559-1567.

18)Insight into the Structure-Antibacterial Activity of Amino Cation-Based and Acetate Anion-Based Ionic Liquids from Computational Interactions with the POPC Phospholipid Bilayer. Physical Chemistry Chemical Physics, 2020, 22: 15573-15581.

19)Controllable Preparation of Nanoscale Metal–Organic Frameworks by Ionic Liquid Microemulsions. Industrial & Engineering Chemistry Research, 2017, 56: 5899-5905.

20)Synthesis of ZIF-8 and ZIF-67 Nanocrystals with Well-Controllable Size Distribution Through Reverse Microemulsions. Chemical Engineering Journal, 2016, 289: 59-64.

21)Computational Screening of Porous Metal-Organic Frameworks and Zeolites for the Removal of SO2 and NOx from Flue Gases. AIChE Journal, 2014, 60: 2314-2323.

(四)燃燒與裂解反應

22)Initial Mechanism and Kinetics of Diesel Incomplete Combustion: ReaxFF Molecular Dynamics Based on a Multicomponent Fuel Model. Journal of Physical Chemistry C. 2019, 123: 8512-8521.

23)Combustion Mechanisms and Kinetics of Fuel Additives: A ReaxFF Molecular Simulation. Energy & Fuels. 2018, 32: 11852-11863.

24)Molecular Simulation of the Catalytic Cracking of Hexadecane on ZSM-5 Catalysts Based on Reactive Force Field (ReaxFF). Energy & Fuels. 2017, 31: 10515-10524.

25)High-Temperature and High-Pressure Pyrolysis of Hexadecane: Molecular Dynamic Simulation Based on Reactive Force Field (ReaxFF). Journal of Physical Chemistry A. 2017, 121: 2069-2078.

【代表性項目】

1)離子液體催化烷基化反應液-液兩相表界面的介尺度機制及調控(國家自然科學基金),80萬元

2)大型精間苯二甲酸生産裝置工藝開發(中國石油),360萬元

3)環己基苯過氧化工藝優化及反應動力學研究(中國石化),150萬元

4)非裂解法烷基化廢酸再生利用技術開發(中國石化),130萬元

5)吡啶酮類香料工業裝置連續化工藝開發(愛普香料集團),250萬元